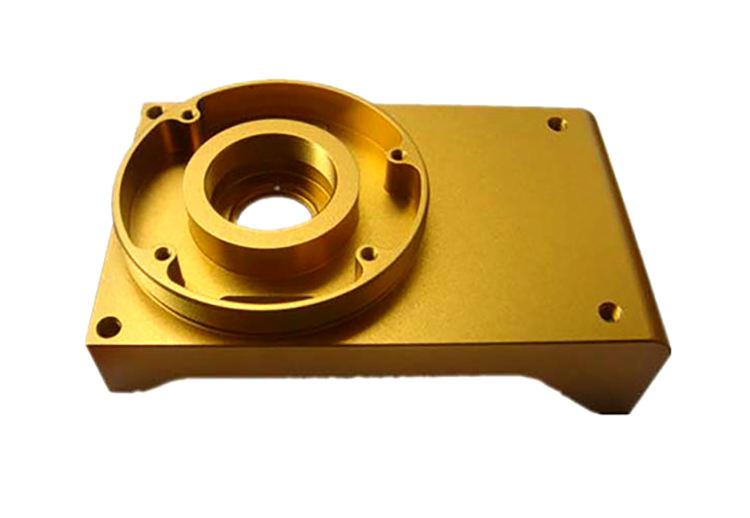

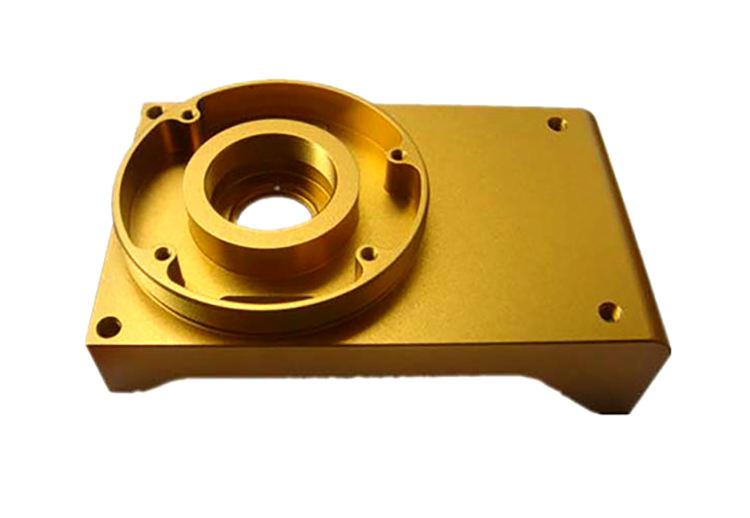

There is a great deal of importance when it comes to accuracy and precision in CNC milling. To produce the highest quality parts and products, all aspects of the machining process must be done with high accuracy. Every step must be precise from machine programming to the actual parts machining to achieve the desired results. Any slight inaccuracy can lead to faulty products that affect the manufacturer’s reputation but also put the consumers’ safety at risk. This post discusses the importance of accuracy and precision in CNC milling and its improvement.

Tips to Improve Precision and Accuracy in CNC Milling

Like other CNC machining processes, CNC milling relies on computers to control the movement of tools. The level of precision and accuracy in CNC machining is controlled by the computer program’s settings that directs tool movement. There are several factors that can affect the precision and accuracy of CNC milling, including the type of material being cut, the condition of the cutting tool, and the accuracy of the machine tool. To achieve the best results, it is essential to be aware of these factors and to take steps to minimize their impact. Making a note of the following helps to improve the accuracy and precision of CNC milling.

Use of Quality Tools:

Although tool movements in CNC milling are automated, quality tools also add value to it. Make sure that you are using tools that are designed for the specific type of cutting. You should also regularly calibrate your machine tools to ensure that they are operated with the highest degree of precision.

Understand the Material Properties:

The material properties such as the tensile strength, yield strength, Young’s Modulus, and thermal expansion of the workpiece need to be considered while machining. For example, a low yield strength material would deform more than a high yield strength material when subjected to the same cutting force.

Upgrade the Machine Tool Promptly:

Nowadays, CNC machine manufacturers add new features and regularly update their firmware to improve productivity. Users may promptly upgrade them to optimize the value of their investments. However, they are reluctant to upgrade the machine tools due to the high investments involved. This may lead to part deformities or machining errors, which may increase product recalls.

Improve Cutting Tool:

Improving cutting tools means using a specifically designed tool for the type of material to be machined. There are different types of cutting tools available, so you should select the one that is best suited for your application to achieve the expected level of accuracy and precision.

Watch an Eye on Tool Wear:

Tool wear results from the abrasive contact between the tool and the workpiece. It causes a decrease in the size of the tooltip and a change in the shape of the tool cutting edge. This can cause the tool to cut inaccurately and produce poor-quality parts.

Material:

The material being machined has a significant impact on the precision and accuracy of the finished product. Hard materials like steel can be machined with greater precision and accuracy than softer materials like aluminum.

Machine Condition:

The condition of the CNC machine also affects the precision and accuracy of the finished product. If the machine is not calibrated correctly or is suffering from wear and tear, the finished product will not be as accurate as it could be.

The other significant factors to consider to improve precision and accuracy in CNC milling include:

Machine tool condition:

The machine tool should be in good condition and accurately aligned.

Workpiece condition:

The workpiece should be free of defects and accurately mounted on the machine table.

Cutting tool condition:

The cutting tool should be sharp and properly ground.

Cutting parameters:

The cutting parameters should be set correctly for the particular application.