The demand for fabricated or machined parts, whether standard or custom made, has surged across industries, and CNC machining is the most preferred method used to perform various techniques to get the required shape and size. It has a high-efficiency level for performing difficult jobs with utmost precision. It can even perform repetitive and mundane jobs with the same accuracy in precision, regardless of the volume. A tool path is basically a path planning pattern which helps complete the workpiece as per the requirement. With the help of CAD/CAM technology, CNC machining shops can create tool paths, which turn complex designing into desired physical parts. The term tool path may sound confusing if you are new to CNC machining. This software offers a series of coordinates that the path follows to meet the exact workpiece requirement. It is a trajectory that a cutting machine tool follows to produce the geometry of the workpiece. Today, almost all CNC machining techniques use this technology, and CNC milling is no exception. Are you intrigued to know more about the term? What is tool path mode? What factors affect tool path mode in CNC milling? If yes, this post answers all these questions in detail. So, stay tuned.

A Brief Overview of Tool Path Mode

As mentioned, the tool path works as a trajectory program during the machining process. CAD and CAM technology stimulates the tool path by creating coordinated locations. The cutting tool follows these locations in the machining process. This, in turn, allows you to detect the involvement of the tool holder and the workpiece alignment, calculate operation speed, and other important things. CNC milling tool paths can be divided into 2D, 3D, 4-axis, or 5-axis, depending on the number of axes the machine has and how they move. Here, you may get confused with the term 2D as there is a z-axis value. However, this value only represents the tool position at a specific depth, constant during the operation. Hence, the 2D label makes sense as the cut operation only happens on the x and y axis.

Factors Affecting Tool Path Mode in CNC Milling

Here is the list of some common factors that affect the tool path mode in CNC milling. So, let’s have a look at them.

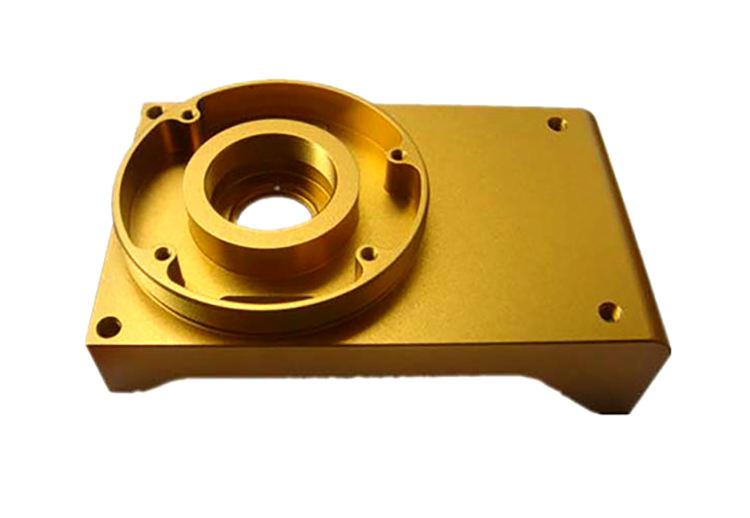

•The first and utmost important factor to consider is the material of the workpiece as it determines the working mode of the tool. Workpiece material does not directly impact the tool feeding, but it will have a direct influence on the selection of the tool size, material, processing methods, and more. The geometric elements of the workpiece, such as shape and size may affect the distribution of the machining allowance of the desired parts to be uniform. Similarly, the workpiece with an optional blank will affect the distribution of processing strategies and the clamping method. This will lead to a different approach for tool feeding.

•Next, clamping and fastening methods will also have an indirect impact on the working mode of the tool. This may include the extra force added to the cutting methods, vibration variation, and much more.

•Another important consideration is tool selection. This may include different parameters, such as material to be used, length of the tool, number of tool teeth, and so on. These parameters make it possible to determine the area and contact frequency between the workpiece and tool. In turn, this helps determine the volume of the final material per unit, the degree of wear resistance, the load of the machine tool, and so on.

•The process route establishes the optimum sequence of operations to realize the machining purpose. Additionally, it also determines the verticals of rough machining, the sequence of processing domains, and partitions or demarcation lines between semi-finishing and finishing. The desired goal can be achieved using various process routes that determine the choices of tool path mode.